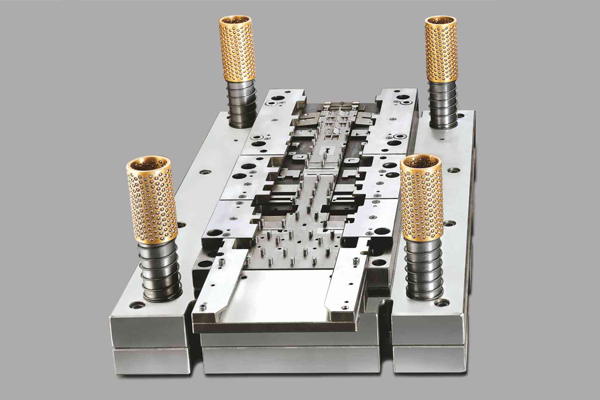

Progressive die stamping involves producing a single part by passing it through different stamping operations. It is contrary to traditional die stamping which produces one part at a time where the ram punches out the desired part in one go. In progressive stamping, the machine manufactures the part by passing it through different stations with a progressive die. The end operation produces the desired component. Progressive die stamping consists of operations like

- Punching

- Coining

- Bending

- Embossing

A progressive die press passes the metal through the various processes as per the prescribed order before delivering the final product. It is similar to an assembly line.

Purchasing progressive die press parts

If you are looking for progressive die stamping to produce complex designs, consult stamping companies with expertise in multiple manufacturing methods. It can prevent potential losses and save time. Leading metal stamping firms like Eigen can help you source quality progressive die stamping parts with zero hassle. Continue reading for more.

Factors to consider before purchasing progressive die stamping parts-

Although progressive die stamping appears to be a simple process, it involves multiple considerations. Before purchasing parts for a progressive die, it is essential to consider the following factors-

Material considerations

One must select materials depending on the final product’s functioning. It is also essential to consider resistance and strength factors. While purchasing a progressive die component, it is crucial to check the tool material.

The most common materials for die stamping involve

- Cold and hot rolled steel

- Brass

- Stainless steel

- Bronze

- Copper

- Aluminium

Shape

Tolerance range is a prominent factor that decides the product’s manufacturing ability. Tolerances usually depend on the part’s form, size, width, and shape. The type of material is also prominent. For instance, cutting steel can lead to sheering and breaks. Hence these factors are also essential when looking for these parts.

Size and material thickness

Progressive die stamping applies to even small parts like fasteners. Hence size is a prominent factor when purchasing progressive die parts. Material thickness also plays a prominent role as it defines the component’s strength.

Volume and Tooling considerations

The tooling consideration depends on the manufacturers as few tools require custom-fit presses. Another factor is the volume of the components. If the manufacturer has a low volume requirement, they can outsource the entire manufacturing to a third-party company. In the case of high-volume production, it is better to purchase these stamping parts to save extra costs of transportation, loading, and unloading.

Final thoughts

One must consider the above factors when purchasing die-stamping parts. It is always advisable to consult reputed suppliers that guarantee quality and service to ensure high-quality parts. Moreover, one can also outsource their manufacturing requirement to avoid extra costs and save time. It also saves additional charges like transportation and material sourcing. Always select a manufacturing company that is well-versed in different manufacturing processes.

Read More: Wafer Dicing Services